PELICE 2024 TOUCHES ALL THE BASES (AND THEN SOME) AS ATTENDANCE SETS RECORD

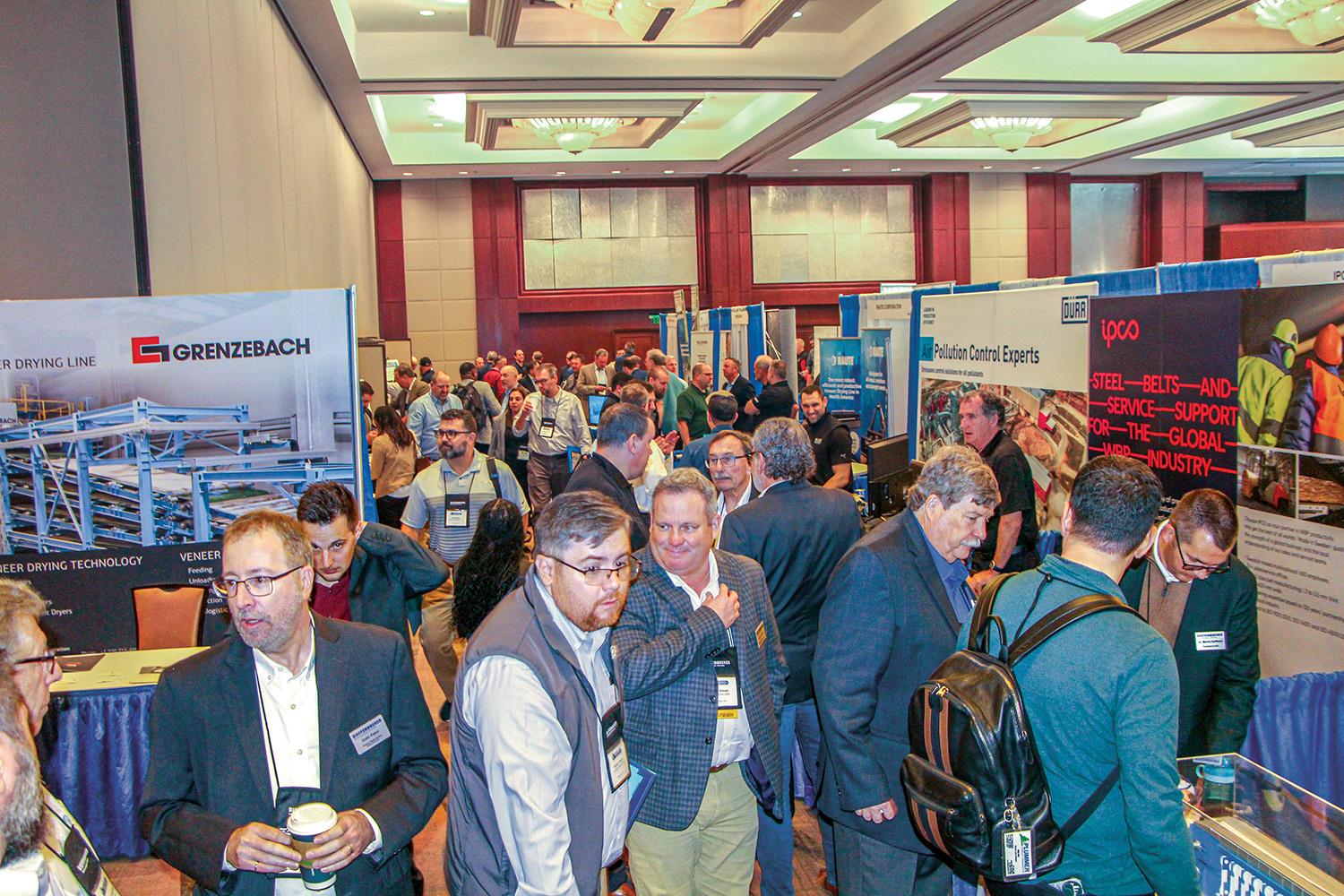

ATLANTA, Ga. – The ninth Panel & Engineered Lumber International Conference & Expo (PELICE) achieved a participation record with 516 industry professionals (producers, equipment representatives, consultants, etc.) attending on-site March 14-15 in the Grand Ballroom North of the Omni Atlanta Hotel at Centennial Park in Atlanta, Ga.

Approximately 30 mill-producer companies from both the structural and non-structural wood products segments sent personnel to take in 35 presentations, explore the aisles of 100 exhibitor technology companies, and enjoy the ample food festivities. Many equipment and mill companies took advantage of the gathering to conduct private meetings around the conference.

“I thought it was going to be a good one going in, but you never know,” commented Rich Donnell, co-chairman of PELICE and editor-in-chief of Panel World, which co-hosts the event along with Georgia Research Institute. “Once we saw the number of walk-up registrations on the first morning, we knew we were on our way, but what really impressed me was the enthusiasm and positive energy that ran through the entire conference.”

Donnell referred to the 2020 and 2022 conferences—the former held when COVID broke out in the U.S. and around the world, and the latter during a post-COVID coming out party as the wood products industry had revved up with record pricing and demand. “So at least compared to those two, we knew this one was going to be more business-back-to-normal, but it didn’t take long to realize there was a lot of new project and new technology discussion going on, and it didn’t let up,” Donnell says.

Donnell referred to the 2020 and 2022 conferences—the former held when COVID broke out in the U.S. and around the world, and the latter during a post-COVID coming out party as the wood products industry had revved up with record pricing and demand. “So at least compared to those two, we knew this one was going to be more business-back-to-normal, but it didn’t take long to realize there was a lot of new project and new technology discussion going on, and it didn’t let up,” Donnell says.

One of the most talked-about projects has been RoyOMartin’s new OSB plant in Corrigan, Texas, which is starting up and is the company’s second OSB plant on-site at Corrigan, with the first one coming up in 2018. But the leadoff speaker of PELICE, Roy O. Martin, III, chairman and CEO, discussed a much bigger picture: “Navigating Change While Preserving a Culture of Excellence,” and specifically looking at what will change and what should not change for a company that turned 100 years old in 2023.

Martin noted that the company remains 100% family-owned and that the past decade has been its “golden decade” as evidenced by the expansion into East Texas and the modernization of their plywood facility in Chopin, La. “The late Jonathan Martin and I were expected to drive the company into the ground as many third-generation owners do, but I am pleased to say that is not the case,” Martin said. “I firmly believe we are entering our second century of business better managed, safer, better prepared financially, and more modern than at any other time in company history. We are built to last.”

Martin said he was proud of the company’s employee benefits, including a medical home staffed by an MD, three NP’s, and a nutritionist, a company pharmacy, and each plant having one or two registered nurses for employees and their dependents. He said their profit-sharing plan has contributed on average an amount equal to 25% of eligible wages each year for the past four years, though he expects that to soften a little bit. Noting that he is on the 18th fairway of his career, Martin asked: “How do we transition to a family-owned, professionally managed, and ethically run company for the next 100 years without me or a Martin as CEO?”

He pointed to failures of several well-known operations such as Circuit City that were supposedly “built to last.” “These companies were over-expanded and over-leveraged,” Martin said. “Yes, ROI to investors is much higher if you are leveraged eight to one as long as you have no problem making a profit off the leverage, the economy never turns down, foreign competition never hurts business, and so on.” He acknowledged that even the best of companies with the best of business plans can go awry when “black swan” events like the Great Recession hit, though he said RoyOMartin was able to run 24/7 with no market downtime during the Great Recession because “We maintained a ‘good’ balance sheet and gave ‘ample’ distributions to shareholders. Private equity-style distributions that leave no equity in the company are not a strategy for sustainability.”

He pointed to failures of several well-known operations such as Circuit City that were supposedly “built to last.” “These companies were over-expanded and over-leveraged,” Martin said. “Yes, ROI to investors is much higher if you are leveraged eight to one as long as you have no problem making a profit off the leverage, the economy never turns down, foreign competition never hurts business, and so on.” He acknowledged that even the best of companies with the best of business plans can go awry when “black swan” events like the Great Recession hit, though he said RoyOMartin was able to run 24/7 with no market downtime during the Great Recession because “We maintained a ‘good’ balance sheet and gave ‘ample’ distributions to shareholders. Private equity-style distributions that leave no equity in the company are not a strategy for sustainability.”

Martin emphasized maintaining a fortress balance sheet for their commodity business that is highly cyclical, including disciplined and thoughtful capital expenditures and adequate but measured shareholder distributions. He also highlighted the transformation in manufacturing with the rise of computer-controlled manufacturing lines using artificial intelligence (AI), urging companies to adapt or risk being left behind.

He used the analogy of Kodak, the inventor of the digital camera, which refused to market the idea, thinking it would take away from the film business. Digital cameras did reduce the film market to rubble, Martin said, but someone else besides Kodak became dominant in the digital business. “If technology changes, you must reinvent yourself,” he said.

Martin said AI will transform the manufacturing process, and vendors must lead this change, but be wary of trying to sell systems that are slower and have less quality than current legacy systems. “We as manufacturers do not want to invest in production systems just to get rid of jobs,” he emphasized.

Martin outlined four key lessons: maintaining a fortress balance sheet for the commodity business, intelligently modernizing facilities (including software) to increase productivity and boost the efficient use of natural resources, being the employer and vendor of choice by prioritizing employee well-being and fostering a culture of family, and sustaining all natural resources given by God.

The conference also featured various speakers addressing topics such as advancements in timber innovation, mass timber construction, digitalization, sustainability, and alternatives to wood. These presentations provided valuable insights into the current state and future trends of the wood products industry.

Latest Show News

PELICE 2024 Covers The Bases & Then Some: Martin, Gray, Dieffenbacher Start It Off

The ninth Panel & Engineered Lumber International Conference & Expo (PELICE) set a participation record with 516 industry professionals (producers, equipment representatives, consultants, etc.) on site March 14-15 in the Grand Ballroom North of the Omni Atlanta Hotel at Centennial Park in Atlanta, Ga.

PELICE 2024 Continues To Light Up Scoreboard With New Presentations

Organizers of the ninth Panel & Engineered Lumber International Conference & Expo announced that attendee registration is open for the event, which will be held March 14-15, 2024 at the Omni Atlanta Hotel at Centennial Park in downtown Atlanta…

Register Now!

March 16-17, 2026 | Atlanta, Georgia

PELICE is the Educational Event for the Worldwide Wood Products Industries Including Veneer, Plywood, OSB, MDF, Particleboard, Engineered Wood Products, Mass Timber and Value Added